Discover insights, tips, and stories from the skies — from aircraft buying guides to pilot training.

Published: July 21, 2025

Flying a vintage airplane feels like stepping back in time. The sound, the design, the controls—they tell stories from decades ago. But keeping those engines running smoothly takes effort, knowledge, and a regular maintenance plan. Vintage aircraft engines are different from modern ones, and they need special care to stay safe and reliable.

This guide explains how to maintain vintage aircraft engines in a clear, simple way. If you're new to owning or restoring classic planes—or just looking to brush up on your skills—this read is for you. Now, let’s talk about what makes these engines unique and how to give them the attention they deserve.

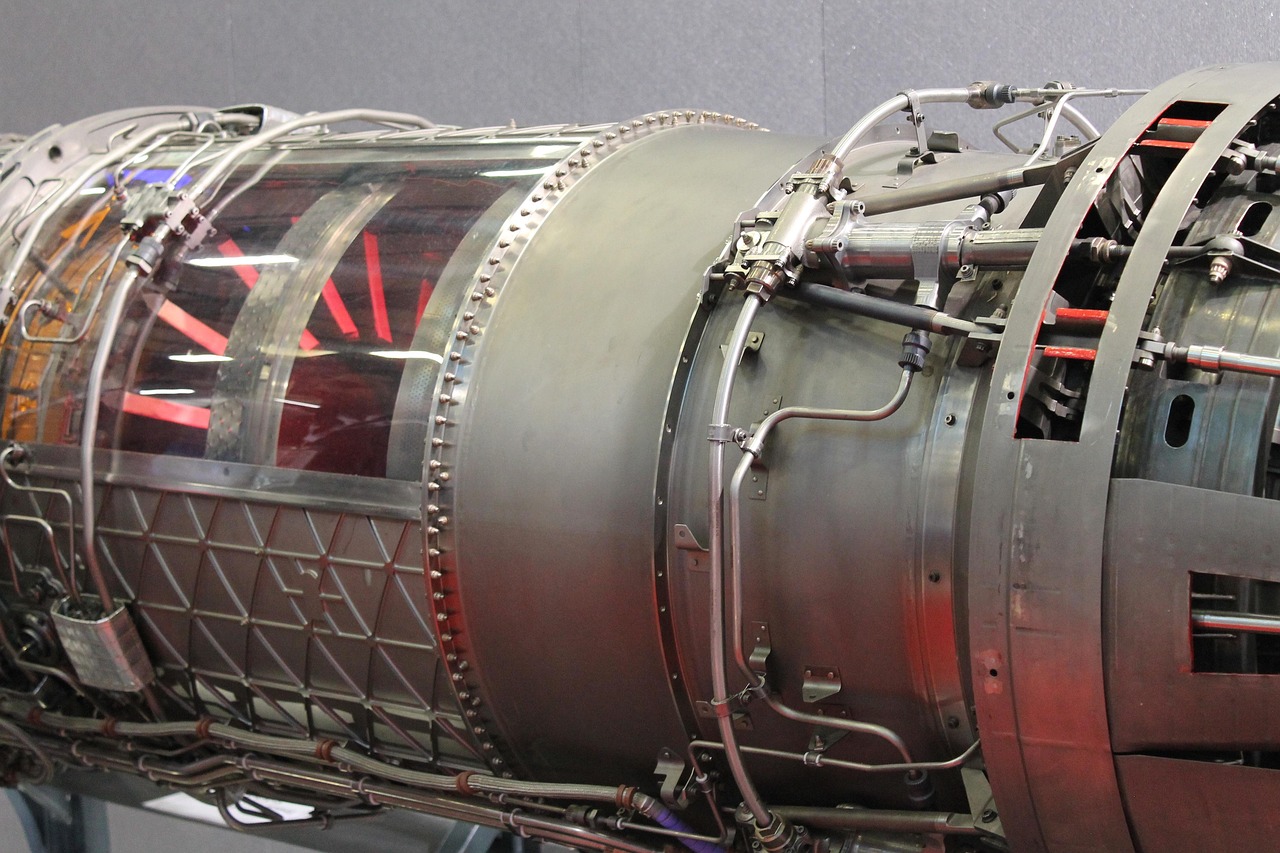

Vintage aircraft engines weren’t built with modern electronics or materials. Most use mechanical systems, like magnetos for ignition and carburetors for fuel delivery. These systems work well—but only if you maintain them properly.

Older engines are often radial engines or inline engines, and both require a different approach than today’s fuel-injected engines. They're made with older metals, and they sometimes run on different fuel types than modern planes. Many of them also need manual priming and preheating before starting.

Here’s a look at what sets them apart:

Understanding these basics helps build a solid foundation for your vintage aircraft engine maintenance routine.

Vintage engines can run reliably—but only if they’re well cared for. Neglect, improper handling, or bad storage can cause rust, leaks, or even full engine failure.

Here’s why regular maintenance is critical:

Vintage engines also need occasional aircraft engine overhaul guide checks to keep things within FAA limits. Whether you’re flying, restoring, or storing, aviation engine care for classic planes is a full-time commitment.

If you’re wondering how to keep old aircraft engines running, it starts with routine habits and ends with a deep respect for these historic machines.

Keeping vintage engines running well comes down to routine. Skipping simple steps can lead to big problems. That’s why every pilot or mechanic working on an old engine needs a plan—and a checklist.

Here’s how to keep things running smoothly.

Before each flight, follow a basic set of steps. This helps catch issues early.

These steps should be part of every pre-flight check for vintage aircraft engines.

If you fly often, some tasks don’t need to happen every day—but they shouldn’t be skipped for long.

These habits are the foundation of airworthy vintage engine maintenance. The more consistent your routine, the longer your engine will last.

Even with great care, every vintage engine will need repairs at some point. Parts wear out. Seals break. Time takes its toll. Knowing what to look for—and how to fix it—can save time, money, and stress.

Start simple. Listen to the engine. Smell the oil. Watch how it starts. These clues help build a repair plan.

Here are a few quick vintage engine troubleshooting steps:

These are the first steps in repairing vintage airplane motors before anything major is taken apart.

Sometimes, the only option is a full overhaul. This means removing the engine, inspecting every part, and replacing or reconditioning worn items. Every overhaul should follow a trusted aircraft engine maintenance guide.

Here’s how it typically works:

It’s a big job, but it’s key to keeping vintage airplane engines airworthy.

Sometimes planes don’t fly for weeks—or even months. That’s when proper storage matters most.

Follow this basic vintage airplane engine storage guide:

These aircraft engine preservation methods help with long-term care, especially in humid or dusty climates.

If you own a radial engine, you already know they need extra love. Make sure to:

To maintain radial aircraft engines, you’ll also want to follow manufacturer-specific guidelines and keep an eye on oil pressure and cylinder temps during flight.

If your plane fits into a rarer category—like a warbird—use focused engine care tips for warbirds or reach out to a mechanic who specializes in legacy aircraft engine support.

Maintaining classic airplane engines is a rewarding task. With the right tools, schedule, and mindset, you can keep these amazing machines alive for years to come. From routine oil changes to smart storage, every step you take adds life to your engine and safety to your flights.

So, how to maintain vintage aircraft engines? Start simple. Stay consistent. And when in doubt, ask a trusted mechanic or restoration pro.

Looking for more tips, expert help, or classic engine services? Reach out to Flying411 today—we’re here to keep your engine flying strong.

A full inspection should be done every 25–50 flight hours, depending on engine type and use. Storage inspections should happen every few months.

Drain fuel, add preservation oil, cover all openings, and store in a dry, temperature-stable space. Follow proper airplane engine storage tips.

Use mineral oil for break-ins and approved aviation-grade oils for ongoing use. Check your engine model and FAA guidelines.

Vintage engine parts sourcing may involve specialty shops, salvage yards, or custom fabricators. Join classic aviation forums or networks.

If you notice power loss, odd noises, or metal in oil filters—or if you hit the TBO (time between overhauls)—it’s time to consult the aircraft engine overhaul guide.